SS round bar

Home » Our Product » Wires , Bars & Rods » SS round bar

Our Products

SS round bar

Get In Touch

Connect With Us for Quality Products and Service

We’re always ready to assist you with your requirements. Whether you need more information about our products, want a custom quote, or have a specific project in mind, the team at Rajgor Impex is here to help. Reach out to us through phone, email, or our contact form, and we’ll get back to you promptly. Your satisfaction is our priority, and we look forward to building a lasting partnership with you.

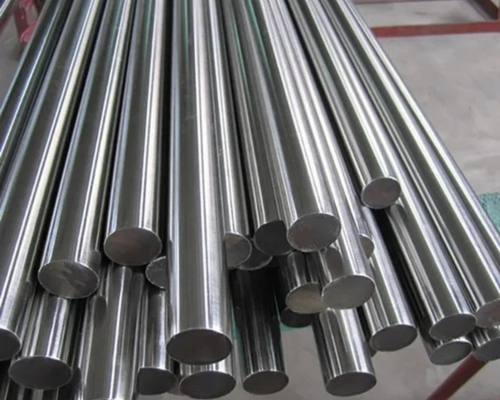

Reliable SS Round Bars for Automotive and Machinery Industries

Rajgor Impex is a trusted supplier of high-quality stainless steel (SS) round bars, catering to diverse industrial needs. Renowned for their commitment to quality and precision, Rajgor Impex offers a wide range of SS round bars in various grades, sizes, and finishes. These bars are manufactured using advanced techniques to ensure durability, corrosion resistance, and consistent performance, making them ideal for applications across construction, engineering, and manufacturing sectors. The SS round bars supplied by Rajgor Impex are known for their superior craftsmanship and adherence to international standards. Whether for structural purposes, machine components, or decorative fixtures, these bars can be customized to meet specific project requirements. Rajgor Impex emphasizes quality assurance, providing clients with products that have a bright, smooth finish and precise dimensions, ensuring seamless integration into any fabrication process.

Features Of SS round bar

- High Corrosion Resistance

- Excellent Strength & Durability

- Smooth Surface Finish

- Heat & Temperature Resistance

- Machinability & Weldability

- Wide Range of Grades

- Dimensional Accuracy

Application Of SS round bar

- Construction & Infrastructure

- Automotive Industry

- Machinery & Equipment

- Oil & Gas Industry

- Food & Dairy Processing

- Pharmaceutical & Chemical Plants

- Fabrication & Manufacturing

Specification Of SS round bar

| Dimensions | ASTM, ASME, API. |

| Thickness | 5 mm To 500 mm |

| Size | from 2.00mm to 6.35mm (0.078″ to 0.25″) dia. |

| Finish | Bright, Black, Polish |

| Form | Round Bar |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Other Services | Machining (CNC), Centreless Grinding (CG), Heat Treatment, Anneling, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication |

| Stainless Steel | AISI 202, 301, 302, 303, 304, 304L, 310, 316, 316L, 317, 321, 347, 410, 416, 420, 430, 431, F51, F53, F55, F44, UNS S21800, Alloy 20, 904L, PH13-8Mo, 17-4ph, 15-5ph, 17-7ph, Ph15-7 Mo, 254Smo, Al-6Xn, 654SMO, duplex 2205, duplex 2507, nitronic ferralium 255 |

| Carbon Steel | ASTM A105 / ASME SA105, ASTM A350 LF2, LTCS. |

| Alloy Steel | AISI 4130, 4140, 4142, 4145, 4150, 4320, 4330, 4340, 4350, 4620, 4820, 6150, 8620, 8630, 8822, 9310, 52100, HY80, HY100, 9315, 300M, Nitralloy 135M, 17-22A, 42CrMoA, EN19, SAE 4140, EN24 |

| Nickel Alloy | Nickel 200, Nickel 201, Monel 400, Monel K-500,Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy B, Nimonic 75, Nimonic 90, Nimonic 80A, Inconel 600, inconel 601, inconel 617, inconel 625, inconel 718, inconel 725, inconel X-750, incoloy 800, incoloy 800H, incoloy 800HT, Incoloy 825, Incoloy 926, Incoloy 890, Incoloy 925, Incoloy A-286, Udimet 500, Rene 41, Waspalloy, Invar 36, Invar 42, Stellite 6B, Kovar alloy |

| Tool And Die Steel | AISI 6F7, AISI A2, AISI O1, AiSI O2, AISI S7, AISI D6, AISI S1, AISI D2, AISI A6, AISI O7, AISI L2, H13, H11, H12, AISI L6, H21, H10, H10A, H19, 314, H19A, P20, P20+Ni, P20+S, S136, 718, SKT6, SKD12, SKD1, SKD2, SKS3, SKS41, SKS95, SKD11, DC53, SKS43, SKD61, SKD6, SKT4, SKD5, SKD7, SKD62, NAK80 |

| Titanium | 6AL4V, Commercially Pure, Grade 2, Grade 7 and Grade 12 |

| Aluminum | 2014, 2024, 2025, 2219, 2618, 3003, 5083, 6061, 7049, 7050, 7075, 7079, 7149, 7150, and 7175 |

Our Products

Inquire Here